New vaccines in three days

Freiburg, Jan 03, 2019

BioCopy produces biomolecule copiers. The University of Freiburg-based start-up wants to make its invention as essential to biolabs as photocopiers once were to offices. It has the potential to accelerate the production of vaccines, medical tests and active pharmaceutical ingredients – or to enable the development of innovative bacteria, which could for example produce plastic from manure.

The laboratory produces vaccines, but before the remedies can be licensed for sale they must undergo thorough testing. Photo: kerkezz/Fotolia

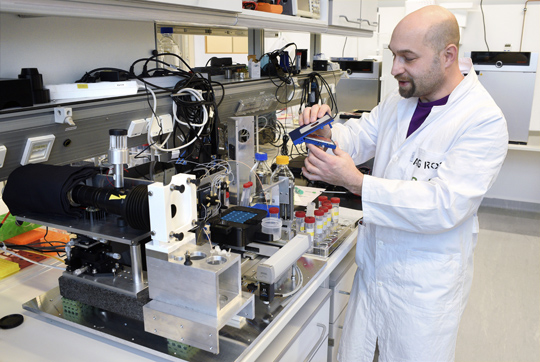

Page of text in, duplicate out? The biomolecule copier of BioCopy GmbH is not quite as speedy as a photocopier. However, the Freiburg start-up’s invention could have similar impact. “This basically makes it possible to produce new vaccines in two to three days,” says CEO Dr. Günter Roth. The normal method takes at least a few months. The biomolecule copier originated from the Department of Microsystems Engineering (IMTEK) at the University of Freiburg. It may revolutionize other fields of medical and biological research too. Roth hopes that his new development will become as indispensable to biolabs as photocopiers are in the office. The American company Xerox, which built the first photocopier, is the model for another ambition – his greatest.

Prizes in the dozens, millions in external funding

“I’d like to establish a research campus, like Xerox in Palo Alto,” Roth says of his dreams for the future. The Californian campus was home to the first minicomputer with a graphic user interface and hand-carved mice made of wood. Here, Bill Gates and Steve Jobs gathered ideas for their later successes with Microsoft and Apple. An ambitious dream – but the innovation of BioCopy has scooped more than a dozen prizes. “In total we’ve already attracted a good 3.5 million euros of external funding,” Roth continues. The biomolecule copier holds enormous potential. It could considerably accelerate the development of vaccines and active pharmaceutical ingredients, likewise of tests to optimize gene therapy and make medical diagnoses, or of organisms with special capacities such as the ability to fight cancer, produce plastics from manure, and much more.

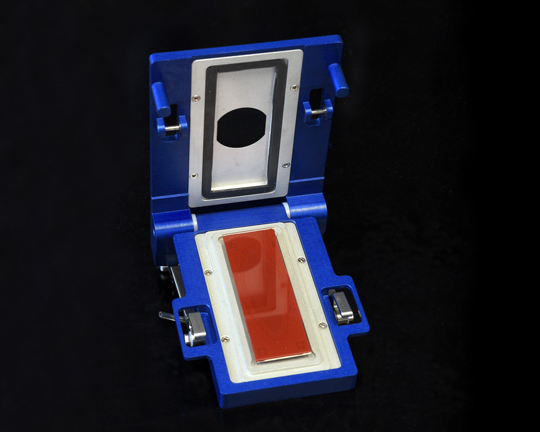

The biomolecule copier takes the format of glass specimen slides used for classic optical microscopes. However, its base is a metal plate with a structured layer of rubber on top. On its surface it has up to 100,000 tiny indentations, or cavities. The microscope reveals a wave pattern – and even particles of dust appear monstrous in comparison to the cavities, but DNA fits in them. “We need these to obtain things like vaccines against viruses that don’t have any,” says Roth. It is not necessary to know the sequence of the viral genotype. Put extremely simply, Roth and his team cut up the virus DNA and distribute the pieces over the rubber chip so that each cavity contains just one piece of DNA. Roth calls this “DNA pixels on a DNA microarray”. In the next stage he uses this to produce proteins. Now he has a chip with all the proteins of the relevant virus on its surface – one piece of protein per cavity.

The biomolecule copier has already brought Günter Roth and his company more than a dozen awards. Photo: Thomas Kunz

Vaccine from the blood of survivors

“Now we need the blood of a survivor,” says Roth. Their immune system must have produced special antibodies in defense. These only recognize and bond with specific proteins from the pathogen, called X and Y in the following example. When the scientists put the survivor’s blood on their chip with the virus proteins, a reaction takes place: antibodies bond to X and Y, but only in the cavities where these proteins are. “We can measure where a bond occurs and how strong it is,” says Roth. For instance, the bond with X in cavity A-15 might be weak, but that with Y in D-23 could be very strong. Then Roth reverts to the chip with the virus DNA, detaches the DNA from cavity D-23, and sequences it, in other words, determines the sequence of its components. “So we already know what type of protein Y is by the next morning,” says Roth. And with the piece of D-23 DNA he can also produce this protein.

This means that Roth has an active vaccine in hand: if people are vaccinated with the Y protein, their immune system produces antibodies against it and can fight off the virus. So much for the theory. “I might inject myself and other members of the laboratory team with the vaccine, if the virus is a potential killer,” muses Roth out loud. The risks have to be clear: it is not possible for an active virus to develop from one or two artificially-produced proteins. However the vaccine has to undergo a compulsory series of tests before wide use. Roth’s next goal is to get a new, effective and harmless vaccine ready to launch. And it is possible to do an extraordinary amount with the biomolecule copier.

Slides are used as “photocopy paper”

One question is, why is the device called a “copier”? “Based on the DNA we can produce as many copies as we like in the form of DNA, RNA and protein,” says Roth. In very simple terms, he presses a glass slide onto a DNA rubber chip. “The glass is our photocopy paper,” is how Roth describes it. DNA sticks to the glass slide, and tests can then be run on it. Roth can use the original, the DNA rubber chip, as often as necessary. He can repeatedly propagate the DNA on the chip, transfer it to a new slide and so on. For duplicates of proteins and RNA BioCopy simply has to put different biochemicals into the cavities. But to begin with it is all about DNA.

Copying made easy: the device presses a glass slide – what you might call the photocopy paper – onto a DNA rubber chip – the original. DNA sticks to the glass slide, and tests can then be run on it. Photo: Thomas Kunz

“The idea is all the fault of a Bosch foundation,” Roth explains. It awards scholarships for risky research which if successful would have great impact. This brought Roth at IMTEK the funds for his first PhD student, who went on to develop the DNA copier. Roth received further funding from winning an ideas competition held by the Federal State of Baden-Württemberg, some EU projects and in 2016 a further 1.65 million euros through VIP+ funding from the Federal Ministry for Education and Research (BMBF). “They’re interested in using cool discoveries for industrial applications,” Roth says of the project. The undertaking will run until autumn 2019. Its outcome, a copier specially designed for analytics, is in the prototype phase. Meanwhile, HaloBind “photocopy paper” for proteins is already on sale – and the start-up says it stores for longer, and is faster and easier to use than the current market leader.

A close fellowship

Freiburg’s BioCopy GmbH has existed since 2016. In September 2018, BioCopy Holding AG based in Aardorf, Switzerland, came into being. “The first investor comes from Switzerland,” Roth explains. One of the four founders of BioCopy is Niko Bausch, who handles the finances and previously worked at the Founders’ Office of the University of Freiburg. “The Founders’ Office and sponsorships have supported us extremely well,” praises Roth. Seven patents protect the biomolecule copier worldwide against illegal copiers. The other three founders are part of the BioCopy research team: alongside Roth there is also Dr. Jürgen Burger and PhD student Christin Rath. Both have worked on Roth’s team since 2011. The 42 year old is delighted about the scientific and economic success of BioCopy. Yet he is almost as enthusiastic about how closely his crew stick together, “We’re a close fellowship – almost like a family business.”

Jürgen Schickinger