Eco-Friendly Batteries

Freiburg, Sep 24, 2018

Very thin, flexible and pliable, and able to be charged in no time – the rechargeable batteries developed by professor of chemistry Birgit Esser are suitable for use in all devices that call for thin batteries with low power consumption. They are perfect for use in so-called intelligent clothing or implants.

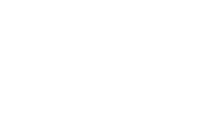

Interesting composition: The side of the electrode pointing upward contains the mixture of active plastic and carbon black. Photo: Klaus Polkowski

Eco-friendly batteries – doesn’t that sound like an oxymoron? Not for Prof. Dr. Birgit Esser: Her batteries are not made of plastic, so they don’t contain any toxic heavy metals, can be charged quickly, and have a long life. “I like it when my research has a practical bearing,” says the researcher, who works at the University of Freiburg’s Institute of Organic Chemistry. Upon completing her PhD, Esser didn’t want to devote herself exclusively to fundamental research and new organic molecular units but was also interested in potential practical applications. The Freiburg chemist asked herself whether these molecular units might be suitable for carrying an electric charge and thus for replacing the toxic heavy metals used in conventional batteries. “That is also interesting for the students. They are much more willing to experiment with various chemical structures of plastics if it doesn’t all end up in the garbage can but has a concrete use.”

Mobile phones, laptops, electric cars: Without powerful batteries, the digital revolution would look a whole lot less revolutionary. The triumphant progress of the lithium-ion battery began in the early 1990s. Up to 30 different metals are used in a single smartphone alone. Mercury, manganese, lead, and cadmium are not just poisonous for humans and the environment; they are also seen as “blood” or “conflict” minerals: Often extracted under exploitative working conditions in conflict zones like the Congo, they are used by armed militias to bankroll bloody civil wars. This gives an ethical dimension to the research Esser and her team of nine are conducting together with their colleagues at the Battery Competence Center of the University of Münster.

Experimenting with Polymer Synthesis

The basic component of the new battery material is a tiny amount of white powder: a polymer plastic by the name of polyvinylphenothiazine. The main work in the lab consists in experimenting with polymer synthesis to test out various structures and paths of synthesis. Since this plastic is not conductive on its own, the scientists add a tiny bit of carbon black to it, by which means it can conduct electricity. Then they mix in a binding agent and a small amount of solvent to obtain a deep black gel. Using a pipette, they spread a thin film of the gel over a piece of aluminum foil. The aluminum foil serves as a collection surface for the active material. As the film dries, the solvent evaporates. Finally, they punch a disc the size of a fingertip out of the coated aluminum foil – the electrode is now finished, and so is half of the battery. All it needs now is an opposite pole.

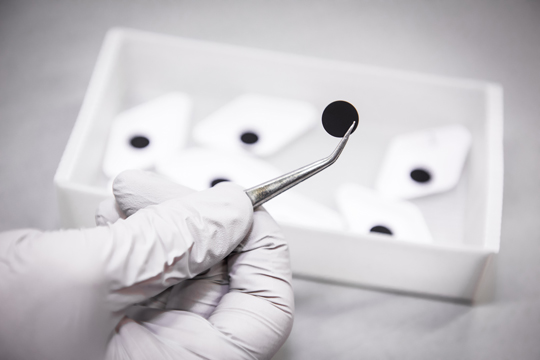

Countless battery models are connected via a tangle of cables to a so-called battery cycler. All laboratory batteries are simultaneously charged and discharged without interruption. Photo: Klaus Polkowski

The electrodes in conventional batteries consist of different types of metal oxides. “We have replaced the heavy metal oxide on the cathodes with organic material,” explains Esser. The cathode is the electrode into which electrons flow as the battery is discharged. The electrons are given up by the opposite pole, the anode. Hence, an oxidation reaction takes place here during the discharge process. It will still be some time before the Freiburg laboratory is capable of producing an entire battery out of plastic. The anode is still made of lithium. “It’s more difficult to develop a suitable organic material for it,” the professor says. “Not just any plastic will do. Many plastics aren’t durable enough.” However, Esser and her team are working on developing organic plastic materials for the anode as well. Their ultimate goal is “to develop a battery that consists of polymers on both sides.”

Extremely Short Charging Times

The test installation is a t-shaped metallic pipe with three openings that looks like it could have also been ordered from a sanitary goods retailer. The plastic cathode developed by the scientists is placed on the one side, an electrode made of pure lithium on the other. Between them, as with all batteries, is a membrane that serves as a separator. Without it, the battery would short circuit as soon as the current began flowing. The third opening of the t-shaped pipe is used to measure voltage. Countless models of this kind are connected via a tangle of cables to a so-called battery cycler. All laboratory batteries are simultaneously charged and discharged without interruption. All processes that take place in the battery cell are measured and recorded over the course of several days or even months. The monitor next to the cycler shows a lot of purple and green charging and discharging curves.

It would be possible to power a mobile phone with eco-friendly batteries. However, the battery would weigh three times as much as a conventional one. Photo: Mirko/Fotolia

In terms of voltage, the 3.6 volt plastic battery is by no means inferior to a lithium-ion battery. However, it has two-thirds less storage capacity, measured in ampere-hours per kilogram of weight. If you wanted to use it to power a mobile phone – which the chemist says would be possible – you would have to have a battery that weighs three times as much as a conventional battery. It therefore seems unlikely that we will see electric cars powered by plastic batteries in the foreseeable future. This also has to do with the low density of plastic. The Freiburg researchers are still working on increasing the density of the active molecule groups but have already applied for a patent for the organic material they have developed for use in the batteries.

Batteries made of plastic could become an interesting alternative wherever thin batteries with low power consumption are called for: for instance in so-called intelligent clothing or in medical technological applications, such as implants. The developers are enthusiastic about the properties of the material. It is very thin, flexible and pliable, and able to be charged in no time. It is a well-known fact that mobile phone batteries take at least an hour to charge, and their performance decreases noticeably over time. The batteries developed in Freiburg and Münster, on the other hand, can be recharged in just three minutes thanks to the disordered chemical structure of the plastic – because here it is not so important whether the counter-ions from the electrolytes arrange themselves at exactly the right point. Lithium-ion batteries, by contrast, are very particular in this respect due to their accurately ordered molecular structure: The ions need to find the one point in the structure where they fit. This takes more time and results in more faulty points when something goes wrong, leading to a clear loss in performance after just 1000 to 2000 charging cycles. The useful life of a plastic battery, on the other hand, seems practically unsurpassable: Even after 10,000 cycles, its capacity is reduced by just seven percent. The only drawback is that plastic is made from petroleum. “However,” says Esser, “it is also possible to develop plastic from biomass.”

Anita Rüffer